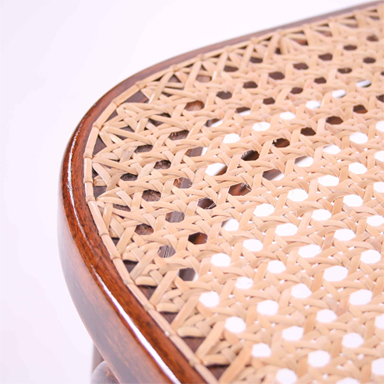

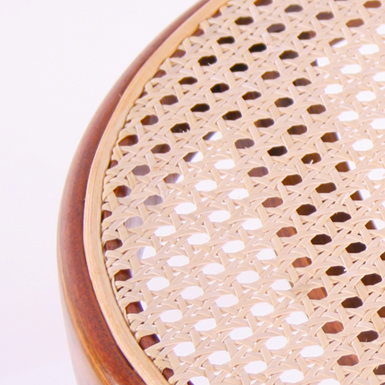

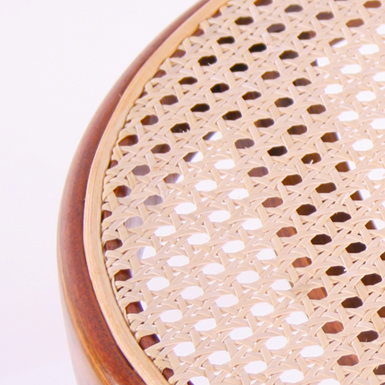

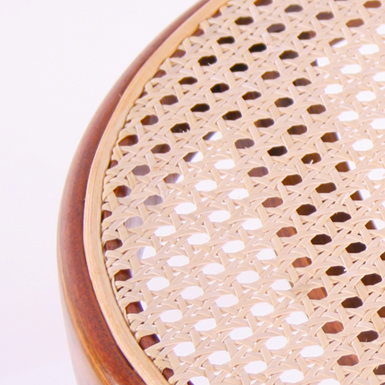

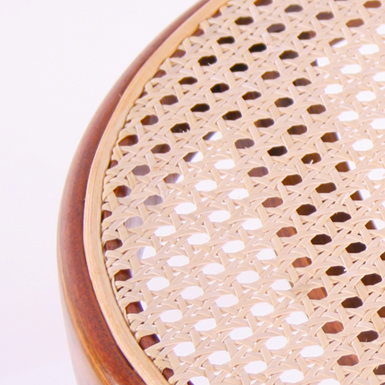

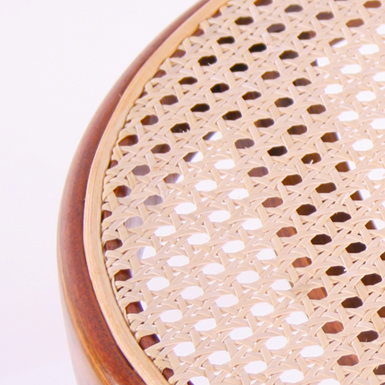

handmade Thonet rattan weaving of chairs and armchairs and also groove weaving

Do you own an old chair or rocking chair with damaged weave? Is the wicker work of your favourite chair broken, or does it show other damage? We offer handmade weaving of Thonet chairs and armchairs with original natural rattan so your chair or armchair provides comfortable and adaptable seating for your pleasure.

handmade weaving

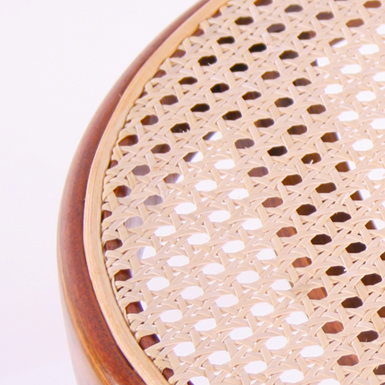

This is a traditional handmade weaving of THONET chairs and armchairs. We exclusively use original natural rattan fibre with diameters of 2.0-3.0 mm. This type of weaving is very time consuming but also very durable.

Price from CZK 7/1 cm2

seat with a diameter of 40 cm = CZK 11,000

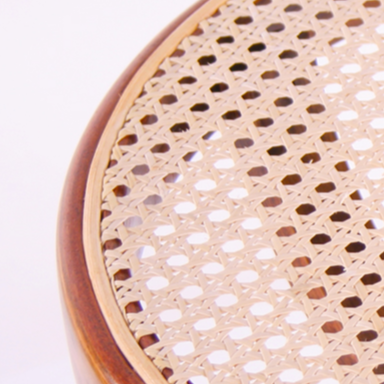

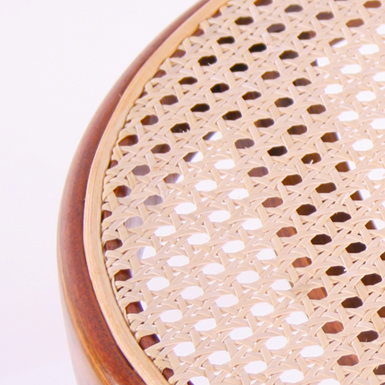

groove weaving

A newer technique of repair with the same material as in the case of handmade weaving, but this weaving is prepared in a footage of different widths and is fixed into a so-called groove. This type of weave is much cheaper but less durable.

Price from CZK 1,50/1 cm2

seat with a diameter of 40 cm = CZK 2.500

The prices do not include any transport or logistics costs and are exclusive of VAT, we are VAT payers (21%).

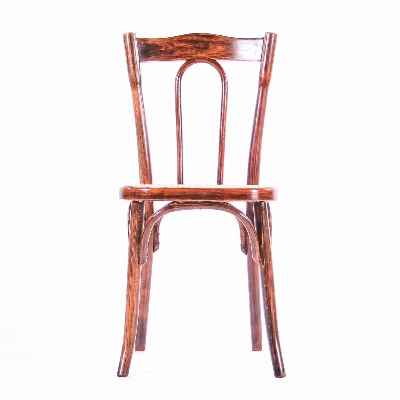

complete period restoration of Thonet articles, including rattan weaving

We offer complete period restoration of historical items of THONET, FISCHEL, GERSTEL, JACOB & JOSEF KOHN, etc., brands. See how sensitively we approach the individual steps of restoration.

-

Dismantling

At the very beginning of the restoration process, each item must be dismantled and disassembled very carefully.

-

Hand sanding with a card scraper

This is a very old and time-consuming but, on the other hand, the most gentle method of removing the original lacquered layers of historical items.

-

Treatment against wood-destroying agents

In its sanded state, it is the ideal time for preventive treatment of wooden parts against wood-destroying insects and other pests.

-

Petrification with resin – hardening

In some cases we use the period method of petrification with resin on a natural resin base for the overall strengthening of historical artefacts.

-

Repair of local defects

In cases where the restored item contains signs of significant damage or even missing parts, we always try to repair or replace the parts locally or sensitively, taking into account the original condition of the part.

-

Stained finish

At this point, everything is in coordination with the investor. We can stain the product to the desired shade, most often we use the original colours, i.e., walnut, oak, beech, chestnut or even a colourless finish.

-

Shellac finish

A key part of the whole restoration process, in our case we use hand-mixed natural-based shellac in several shades. Normally applied by hand, min. 10 layers, always according to the current surface condition. We use different shades of shellac for the final effect.

-

Rattan weaving

We offer two rattan weaving variants. The period method consists of manual pre-weaving, which is a more difficult but more durable repair option. A newer and quicker method is the so-called groove weave, which is significantly cheaper but also less durable variant of repairing the weave.

-

Assembly and final inspection

This is the last part of the restoration process before the actual handover. After assembly each product undergoes a detailed final inspection for strength and durability, and a visual inspection. The product then travels to its owner in different parts of the world. Thank you, with love, A1R.

ARE YOU INTERESTED IN A PERIOD RESTORATION?

what products have we restored?

Ordering a rattan weave or complete restoration of an article