Rattan - rattan - pedig What is it actually about?

Before the production of "thermoplastic plywood" was introduced in Michael Thonet's company in 1877, all seats and some backrests were filled with yarn. Rattan weave for sofas was already about three hundred years old technology in Thonet's time. The material is called rattan, sometimes also ratan. This according to the pronunciation in the former English or French colony of the former Indochina, where this material grows. The name rattan is also part of the scientific name of each geographical variety of this plant, and is therefore more correct.

It is a creeping and climbing palm tree, whose peeled bark is cut into different widths on a completely primitive tool, and the wood is then used to make the well-known rattan furniture.

It is therefore not a reed, as it is sometimes (even in company documents!) - perhaps for simplification - incorrectly written. Also other names "Spanish reed" or "pedig" are trade names for something else, often not used accurately and therefore misleading.

The following rattan fiber widths are mainly on the market today: 2.00 mm, 2.25 mm, 2.50 mm, 2.75 mm, 3 mm and 5 mm. Thonet's Technisches Hilfsbuch from 1909 contains an internal knitting standard. Fabrics for seats and backrests are listed separately. It is assumed that the seat is stressed disproportionately more than the backrest. The standard does not use specific dimensions for the width of rattan, but the numbers under which the Hamburg import companies listed this material. At that time, different materials were still supplied in terms of quality - appearance and strength - which had to be properly differentiated for orders. Today, even from the first class (bundles tied with blue twine), there is often an unbearable amount of unprocessable waste, and restaurateurs are desperately looking for quality material all over Europe.

A. Normal braid (Normalgeflecht) is used for the vast majority of seating furniture. The spacing of the holes is 12 to 14 mm. The width of the fiber is 2.50 mm.

B. We can find fine weave (feines Geflecht) on more expensive older models and on parts of children's furniture. The holes are spaced between 10 and 12 mm, but there are known pieces with spaces as small as 8 mm. The width of rattan is 1.5 to 2 mm. For pitches of 10 mm and less, backrests used to have widths of even 1 mm. In the case of fine and sometimes even normal weaving, a width of rattan with dimensions narrower than that of the diagonal was used for the warp at the border spacing of the holes. Therefore, for pitches of 11 mm, the fine yarn had a warp of 1.5 mm and a diagonal of 2 mm, and a normal yarn with a pitch of 12 mm had a warp of 2 mm and a diagonal of 2.5 mm.

Thonet's standard from 1909 no longer applies to seats with a superfine weave with pitches of 8 to 9 mm. Due to the need to use a fiber with a width of 1.5 mm for the warp and 1.75 mm for the diagonal, durability was not guaranteed.

C. Coarse weave (grobes Geflecht) was only used as a base for low upholstery. Pitches are 15 mm and more. Rattan width 3 to 3.5 mm. As a base for upholstery, the coarse knitting did not have a peripheral end. On the one hand, it was unnecessary, because the string was hidden under the upholstery, on the other hand, it would have caused problems during the upholstery, the upholstery nails had just been hammered into the place of the perimeter thread, it would tear, and parts of it would cause problems during the next part.

The knitting system as such, i.e. a double rectangular warp and two simple diagonals, all with a circumferential finish, was varied here and there. Even before the First World War, two rectangular systems (Viereck-Geflecht and Langol-Geflecht) were introduced among the Thonets. None of them, however, proved themselves due to the increased labor and especially lower durability.

In some backrests, usually it is not Thonet furniture, there are blind holes. The back side of the backrest can thus remain intact and a groove does not have to be milled into it, which - in the case of through holes - must be rather complicatedly covered with a glued-on chip after weaving, cleaned or filled with putty and veneered. Each fiber is inserted into the blind holes, secured with a special mandrel, and finally all fibers are fixed with glue and a pin. This work requires extreme care and patience.

A completely extraordinary drilling system "not through" was discovered on unspoiled furniture quite recently. For short, it could be called "tunnel". The holes are drilled diagonally opposite each other, so they create a kind of tunnel. It is straight in the longitudinal direction, but in depth it forms a wave. The string itself is at first glance like any other, i.e. a double vertical warp with two diagonals. However, the insertion into the holes and the peripheral thread are completely different. Special tools are necessary for knitting, because inserting the thread into the "tunnel" is the usual tool when gradually filling "tunnel" increasingly difficult and work is only for really strong nerves.

However, it seems that this thread was invented relatively recently by someone in Vienna, so that he did not have to undergo the difficult work of covering the groove in the back of the backrest.

Another technique is the so-called fan stitch starting from one point on the bottom, less often on the top side of the backrest, sun stitch starting from the wooden disc in the middle of the backrest. Both of these types of string were only used on more expensive chairs and armchairs. They are quite demanding to produce and require not only know-how, but also a certain routine.

Let's not forget the double weave, which was, however, used only exceptionally on Thonet's furniture. It is mainly found on luxury armchairs from the 1930s.

According to the annual reports, an incredible amount of this natural fiber was consumed annually - at the end of the nineteenth century, when many sofas were made of plywood, the rattan consumption in the Thonet brothers' company was between 65 and 75 tons annually!

Weaving period articles really requires a lot of experience, because every next piece is different. However, it can generally be said that virtually anyone with manual skills can knit really highly and nicely after having knitted about fifty different articles. There are many pitfalls and practice cannot be replaced by description.

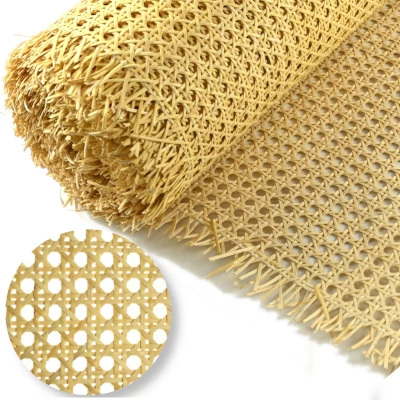

We sell original natural rattan fiber of the highest quality directly from the plantations of the original Indochina

meticulous hand restoration, preserving the spirit of the item and using the finest materials

Each piece of furniture has its own history, sometimes very complex and dramatic, sometimes peaceful. But never ordinary. At the time of creation it was already distinctive and high-quality furniture. The owners knew it. We move its story further, sometimes just by pushing it along, sometimes breathing new life into it. It is only up to you how its story continues.